Global heating technology is developing rapidly, and the environmental protection needs of energy conservation and carbon reduction are becoming increasingly urgent. Some countries and regions have introduced policies to emphasize the urgency of heat metering transformation, and even explicitly proposed to promote the model of charging by heat. Driven by such policies, the importance of ultrasonic flow measurement technology has become increasingly prominent. It is not only the key to achieve accurate heat metering, but also an important tool to promote the heating system to move towards the goal of energy conservation and carbon reduction.

Ultrasonic flow measurement technology : an important technical means to save energy and reduce carbon emissions in heating systems

Ultrasonic flow measurement technology, with its high precision and low loss characteristics, provides a reliable solution for heat metering. This technology can accurately capture the flow velocity and flow rate of the fluid by measuring the propagation time difference of the ultrasonic signal in the fluid, and provide accurate data support for the heat energy distribution of the heating system. This plays a vital role in ensuring the efficient operation of the heating system, optimizing energy distribution, and reducing energy waste.

Ultrasonic flow measurement technology:specially developed for " green" ultrasonic heat meters

In the "smart heating" system, the sensor with ultrasonic measurement technology as the core is like a precise " thermometer " that can accurately measure the flow rate and flow of hot water. The sensor calculates the flow rate by the propagation time difference of ultrasonic waves in the downstream and upstream, and then combines the temperature value measured by the temperature sensor to comprehensively calculate the consumed heat value. This high-precision measurement enables the heating system to control the distribution of heat more accurately and effectively avoid energy waste.

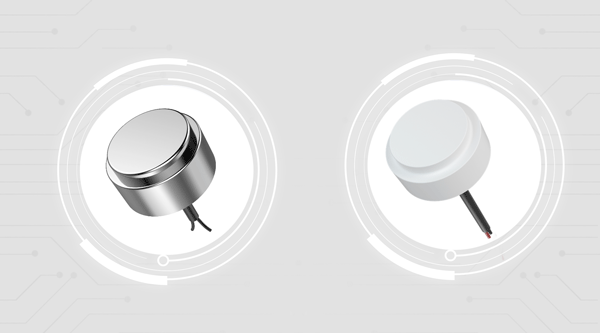

ADW high temperature flow sensor: high temperature resistance, high pressure resistance, high efficiency thermal conductivity

High Temperature Flow Transducer based on the characteristics of thermal measurement. It is made of high-pressure stainless steel and ceramic materials, combined with a highly sealed design, so that the sensor can be in direct contact with the liquid medium, while effectively avoiding pressure and the instability of heat resistance ensures the stability of product performance. This design significantly reduces the interference of environmental factors on the product's output and received signals, thereby significantly improving the product's response sensitivity.

High temperature resistance up to 240℃

The sensor provides two shell materials: stainless steel and ceramic. The stainless-steel shell can withstand high temperatures of 120°C, and the ceramic shell sensor can withstand high temperatures of up to 240°C.

Long-term tolerance of 2.5MPa high pressure

ADW high-temperature flow sensor is very rigid and can withstand a pressure of up to 2.5MPa for a long time. This pressure resistance is far superior to the common 1MPa pressure-resistant sensors on the market.

Metal material, good thermal conductivity

High-temperature flow sensors made of metal have excellent thermal conductivity, which helps the heat meter to more accurately sense changes in fluid temperature during the measurement process and improve measurement accuracy.

Drive voltage as low as 5Vp-p

The driving voltage of this sensor is 5Vp-p, which not only has a low driving voltage, but also meets the testing requirements of many European and American countries, ensuring the consistency of the product.

Strong weather resistance and high reliability

After rigorous testing and verification, ADW high-temperature flow sensor has demonstrated excellent resistance to moisture, thermal shock and vibration, and has excellent overall weather resistance. It can meet the requirements of industrial equipment for high-temperature water metering and has extremely high reliability.

Regular size, wide fit

In terms of size design, the probe diameter of the high-temperature flow sensor is 16.8mm, which perfectly matches the conventional ultrasonic heat meter and ensures ease of installation and use.

Ultrasonic flow measurement technology: helping the heating industry transform towards " digitalization "

Benefiting from the structural advantages of ultrasonic measurement technology, the pipe section equipped with high-temperature flow sensors has no moving parts inside, so it has lower pressure loss and higher accuracy. To further promote the development of the "smart heating" system, ultrasonic flow pipe sections with digital signal output are currently widely used, effectively improving the stability and reliability of data transmission.

This type of ultrasonic flow measurement technology with intelligent expansion will help promote the " digitalization " transformation of the heating industry. Through digital flow monitoring and management, heating companies can monitor the operating status of the system in real time, adjust heating strategies in a timely manner, and achieve more refined and intelligent energy management. This not only improves the operating efficiency of the heating system, but also brings more comfortable and economical heating services to users.

Driven by the active and powerful policies of many countries, ultrasonic flow measurement technology will play a vital role in the field of heating metering. It not only improves the measurement accuracy and operating efficiency of the heating system, but also helps to promote the " digitalization " transformation of the heating industry, and contributes to achieving energy conservation and carbon reduction goals and promoting the sustainable development of the heating industry.