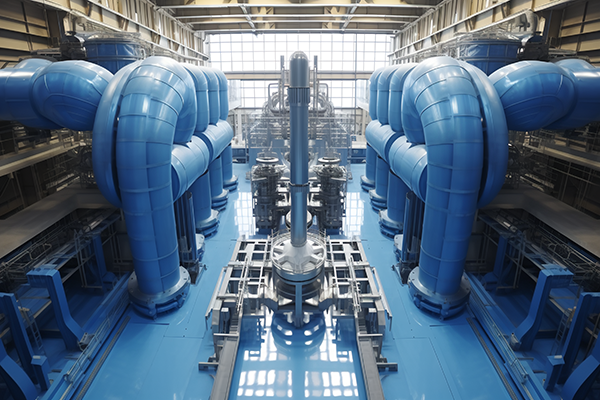

In the industrial field, with the rapid development of the electronic information industry, the replacement of electronic products is accelerating, and the production demand in the corresponding subdivided manufacturing field is increasing. On the other hand, the control indicators of water resources in various countries and regions around the world are becoming more and more stringent. Some countries even require that the daily wastewater discharge of manufacturing enterprises must be approved by the local environmental protection department and no excessive discharge is allowed. In this case, if manufacturing enterprises want to expand production and scale, they must find solutions to save water and increase production without increasing pollution.

ADW intelligent water-saving solution integrates a variety of sensors to detect and output data in real time for remote cloud processing; it can be flexibly adjusted and remotely controlled; real-time flow, daily water consumption, real-time pH value and other data can be easily viewed and managed through mobile phones, computers and other terminals, providing strong technical support for remote management of water systems .

ADW Intelligent Water Saving Solution : Save water, increase production without increasing pollution

To help the manufacturing industry improve quality and increase efficiency, ADW launched its first intelligent water-saving solution. The solution consists of two major parts: intelligent water-saving devices as hardware and intelligent monitoring systems as software. It combines advanced technologies such as multi-source sensing, cloud computing, and two-way communication to provide manufacturing companies with real-time monitoring of flow and water quality changes, remote control of water volume, and intelligent dynamic adjustment of applicable water volume. While ensuring production quality, it achieves green production effects such as energy-saving water use and increased production without increasing pollution.

Rich practical experience, saving more than 15% of water

In the papermaking, textile, steel, PCB printing and other manufacturing industries, product production needs to go through multiple wet processes and consume a large amount of water. Saving water has become one of the key links for enterprises to reduce costs and increase efficiency.

At present, the ADW intelligent water-saving solution has been put into use in many manufacturing companies. Practical experience shows that the solution has obvious water-saving advantages in manufacturing wet process applications. After using the ADW intelligent water-saving solution, three manufacturing companies have saved more than 15% of water, with obvious water-saving effects.

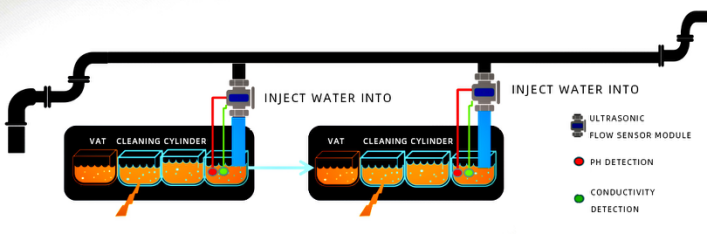

It is understood that the core hardware of the intelligent water-saving solution, the intelligent water-saving device (Ultrasonic Flow Sensor Module) , can be combined with pH sensors, conductivity sensors, etc., and can preset pH and conductivity ranges. If the pH and conductivity of the liquid in the wet process are not within the preset range, the solution will immediately control the ball valve to adjust the water injection speed, and automatically control the ball valve to reset to the original water injection speed after the pH or conductivity of the liquid reaches the set range. Therefore , the application of intelligent water-saving solutions effectively avoids the problems of empiricism, large errors, and inability to accurately control water quality in manual water control, and ensures scientific and high-quality water.

ADW intelligent water saver installation and use reference in wet process

Data on the "cloud" and two-way transmission to achieve efficient management

smart water-saving solution can be uploaded to the industrial Internet platform through 4G or NB network. The visual interface allows people to understand the operating status and parameters of the water system more intuitively and clearly. At the same time, computers, tablets, mobile phones and other clients can synchronize all the dynamics of the water system, and administrators can remotely control the water system anytime and anywhere, which is simple and convenient.

Intelligent water-saving solution integrates a variety of sensors and has a two-way data transmission function. It can upload liquid monitoring data and issue water use adjustment instructions at the same time. The product collects comprehensive water management data through multi-sensor fusion technology, uploads the data to cloud computing, issues instructions based on cloud computing results, and remotely controls the water flow rate of intelligent water savers in different areas and processes. Through closed-loop system instructions, fully intelligent operation is achieved, and the water flow of the production line is dynamically adjusted. Under the premise of ensuring production quality, the green production effect of energy-saving water is achieved.

Product Recommendation:

Ultrasonic Flow Sensor Module

The Ultrasonic Flow Sensor Module measures the flow rate of liquid by calculating the transit time dierence of upstream and downstream ultrasonic pulses. It contains no moving part in the pipe section, and therefore has lower pressure loss and higher accuracy than traditional flow meters.

- No moving parts

- High accuracy

- Low power consumption

- Digital output